From their home base in Hamurana, Rotorua, they’ve expanded their operation to encompass four herds, ranging from 460-580 cows.

“It’s been built up over 40 years,” Chris says. “It’s a bit humbling when you stop and think about it.”

They have one farm in Okoroire, Waikato, and the other three farms are relatively close in proximity to their home farm. However, these properties are separated, one by a road, and another by a gorge which makes the logistics of managing a herd of 1,500- cows complex. Instead, they’ve structured their operation into three distinct milking units, that enables smoother day-to-day management while still allowing them to leverage shared resources and consistent herd strategies.

What sets Tawa Ridge apart isn’t just its size, it’s the way they approach decision-making. With support from their LIC Agri Manager Rosanna Dickson, Chris and Christine have developed a system that brings together technology, data, and long-term thinking to drive results.

“Rosanna has become an integral part of our decision-making team, not just helping interpret the data, but working with us to develop strategies that align with our goals.”

“Since she came on board, we’ve made exceptional herd improvement gains. Rosanna really listens to what we’re trying to achieve and builds our mating plans to suit. It’s not one-size-fits-all, it’s about what works for our system, and our herd,” says Chris.

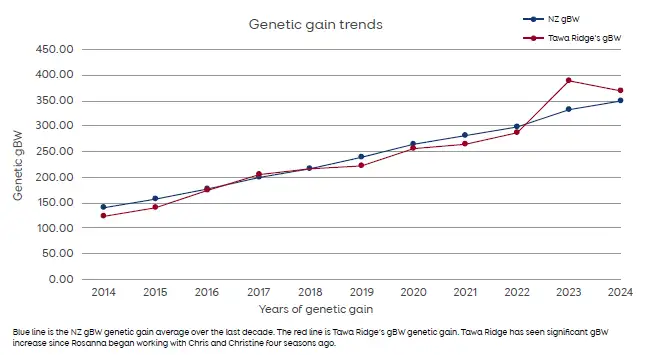

Over the past five years, Tawa Ridge has experienced an average gBW gain of 29, and in the last three years a 35% increase. This performance surpasses the industry average for gBW, which is approximately 19%.

Rosanna’s ability to balance the technical insights with practicality has helped the Tawa Ridge team unlock new opportunities.

“They trust the process, and that makes all the difference,” Rosanna says. “When you’ve got mutual respect and shared goals, that’s when you really start to see results.”

“Additionally, they like data,” Rosanna says, “but like many farmers, they’re often bombarded by it. That’s where I come in, to help make sense of it and take action.”

Rather than making mating decisions based solely on what semen is available, Chris and Christine start with a bigger question: What is the future of each calf born on the farm?

That thinking drives everything they do, from their mating plans to the structure of their replacement programme.

Their young stock programme has around 500-600 replacements reared annually across several runoff blocks. Long-standing relationships, like their calf grazier who has partnered with them for over 30 years, add depth toa system that’s innovative and off-tradition.

While many farmers across New Zealand are leaning into dairy beef to boost returns, Chris and Christine are taking a different route and instead increasing their use of sexed semen. Their goal? Maximise early calving replacements and sell surplus heifers into a market currently short on high-quality young cows.

“We’ve done up to 620 replacements some years,” Chris notes. “This year it’ll be over 600 again. It's a big job, but one that pays off in the long run. We only need approximately 400 replacements across our four operations, which allows us to be very selective in our replacement stock and sell the remaining as R1s.”

Rosanna Dickson, Senior Agri Manager

This excess breeding is intentional and only possible because of their commitment to the “full nine yards of herd improvement tools and data, such as accurate herd testing, extensive use of DNA, and a commitment to health and safety which underpins everything they do. With this foundation, they’re making exceptional culling decisions,” Rosanna notes.

“They once said to me, it feels wrong putting great cows on the truck,’” says Rosanna. “But I reminded them, they’re not culling. They’re supplying other farmers with some of the best replacements they’ll ever buy. These cows are DNA tested, BVD-free, with high PW and BW.”

This shift in strategy has also led them to use SGL Dairy® semen late in the AB period, creating compact calving and bringing cows forward in the calving pattern. It’s a system that generates more days in milk, earlier calvers the following year, and allows for greater options to select top replacements.

“It’s the compounding effect,” says Rosanna. “Every year their herd gets more front-loaded, and that provides more opportunity, more revenue, and more progress.”

At Tawa Ridge, herd improvement isn’t a one-off decision, it’s a system. And it’s working.